3D Printing and Rapid Prototyping: Transforming Modern Manufacturing

The landscape of manufacturing has undergone a radical transformation with the advent of 3D printing and rapid prototyping technologies. These innovative methods have not only streamlined production processes but have also redefined the limits of creativity and customization in metal fabrication. In this comprehensive article, we delve into the intricacies of 3D printing and rapid prototyping, exploring their applications, benefits, and the future they promise for the manufacturing sector.

The Evolution of Manufacturing Technologies

Manufacturing has traditionally relied on subtractive methods—machining away material to create parts. However, with 3D printing, also known as additive manufacturing, industries are shifting towards a more efficient approach. This method involves building parts layer by layer, resulting in several advantages that can significantly enhance production capabilities.

Understanding 3D Printing

What is 3D Printing?

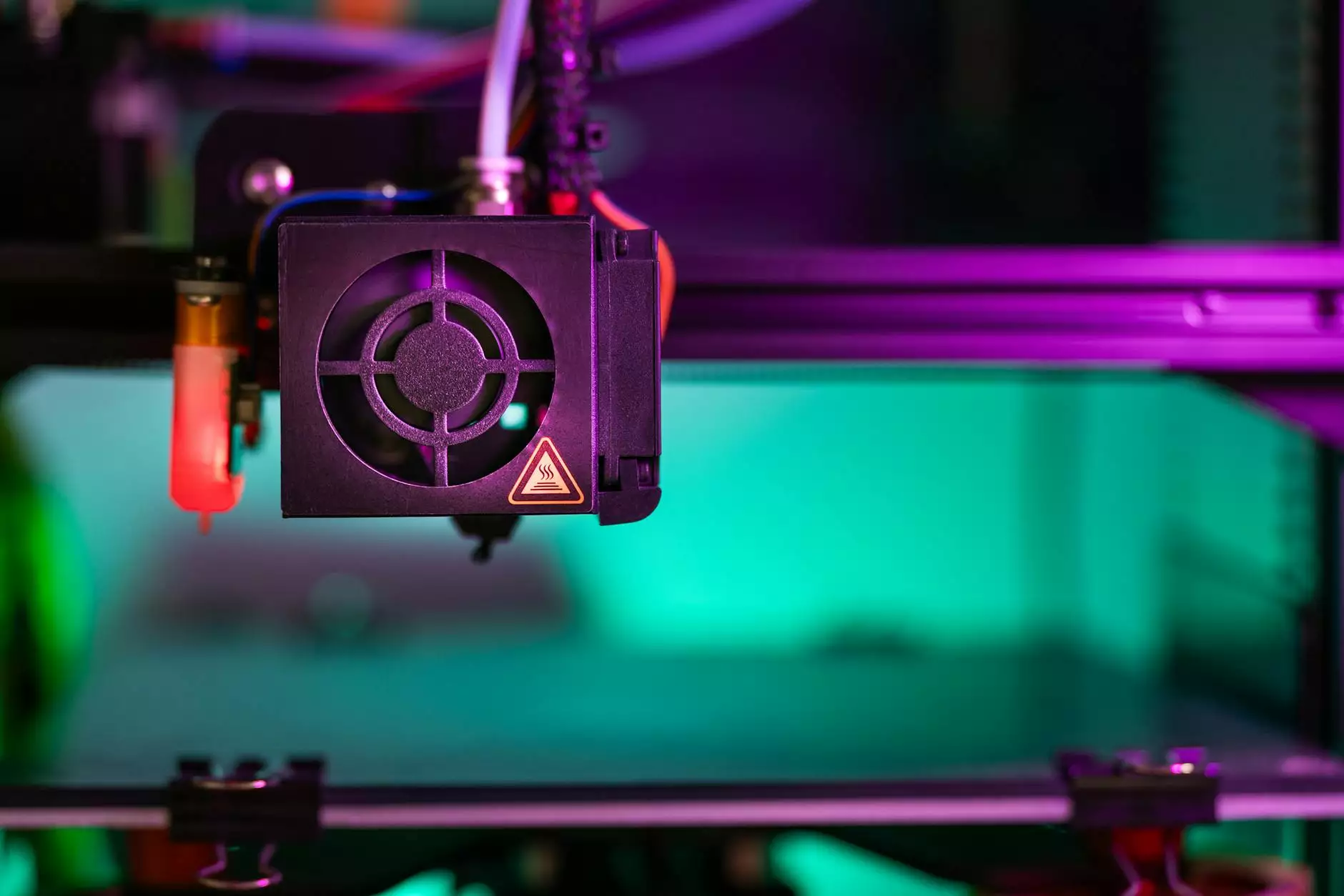

At its core, 3D printing is a process where digital designs are transformed into physical objects. This is achieved through various technologies such as Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). Each of these methods has its own set of applications, materials, and capabilities.

Applications of 3D Printing

3D printing technology has found applications across numerous industries, including:

- Aerospace: Lightweight components are created to improve fuel efficiency.

- Healthcare: Customized implants and prosthetics tailored for individual patient needs.

- Automotive: Rapid prototyping of complex parts and tools.

- Architecture: Detailed models that aid in visualization and design processes.

- Consumer Goods: Personalized products ranging from fashion items to household gadgets.

The Role of Rapid Prototyping

What is Rapid Prototyping?

Rapid prototyping refers to the process of quickly creating a scale model of a physical part or assembly. Utilizing 3D printing technologies, rapid prototyping enables designers and engineers to test and validate their concepts before proceeding to full-scale production. This process is vital in minimizing risks and reducing time-to-market.

Benefits of Rapid Prototyping

The benefits of rapid prototyping are manifold:

- Speed: Prototypes can be produced in a fraction of the time compared to traditional methods.

- Cost-Effectiveness: Reduced material waste and lower labor costs.

- Improved Design Flexibility: Easy modifications can be made to designs based on testing results.

- Enhanced Collaboration: Stakeholders can physically interact with prototypes, improving feedback and decision-making.

3D Printing and Rapid Prototyping in Metal Fabrication

The Intersection of 3D Printing and Metal Fabrication

While 3D printing is often associated with plastics, metal 3D printing is gaining momentum in the manufacturing world. The ability to create complex geometries and lightweight structures has made metal 3D printing a game changer for metal fabricators.

Methods of Metal 3D Printing

Some of the primary methods used in metal 3D printing include:

- Direct Metal Laser Sintering (DMLS): Uses a laser to fuse powdered metal, resulting in highly durable parts.

- Metal Binder Jetting: A method that involves the application of a binding agent onto a bed of metal powder, which is then sintered.

- Electron Beam Melting (EBM): An additive manufacturing process that uses an electron beam to melt and fuse metal powder.

Benefits of Metal 3D Printing

The adoption of metal 3D printing in rapid prototyping offers various advantages:

- Complex Part Geometries: Capable of producing intricate designs that were once deemed impossible.

- Weight Reduction: Ability to create lightweight structures without compromising strength.

- Material Efficiency: Reduction in waste through precise material usage.

- Customization: Tailored parts for specific applications or customer needs.

Challenges and Considerations

Challenges of 3D Printing and Rapid Prototyping

While the benefits are significant, there are challenges and considerations that must be addressed:

- Material Limitations: Not all materials are suitable for 3D printing, especially in metal fabrication.

- Volume Production: 3D printing may not always be the most cost-effective method for high-volume manufacturing.

- Post-Processing Needs: Many 3D printed parts require additional finishing processes to achieve the desired surface quality or mechanical properties.

The Future of 3D Printing and Rapid Prototyping

Trends Shaping the Future

The future of 3D printing and rapid prototyping is bright and is being influenced by several trends:

- Increased Material Diversity: Ongoing research is expanding the range of materials available for 3D printing, including advanced alloys and composites.

- Sustainability Initiatives: 3D printing is being explored as a way to reduce the carbon footprint of manufacturing processes.

- Integration of AI: AI and machine learning will likely enhance design capabilities, optimizing prototyping and production processes.

- On-Demand Manufacturing: The shift towards decentralized manufacturing means that products can be printed as needed, reducing inventory costs.

Conclusion

The impact of 3D printing and rapid prototyping extends far beyond enhancing manufacturing processes; it is fueling innovation and reshaping industries. As technologies advance and materials evolve, metal fabricators and manufacturers stand to benefit immensely from these methodologies. The integration of additive manufacturing will not only drive efficiency and reduce costs but also support the development of truly customized products that meet the increasingly sophisticated demands of consumers and businesses alike.

Why Choose DeepMould.net?

For businesses looking to harness the power of 3D printing and rapid prototyping, DeepMould.net stands as a trusted partner. With a range of services tailored to the needs of the metal fabricators sector, we offer cutting-edge solutions that leverage the latest advancements in manufacturing technology. Our commitment to quality and innovation ensures that you stay ahead in a competitive landscape.

Embrace the future of manufacturing with DeepMould.net and experience firsthand the benefits of integrating 3D printing and rapid prototyping into your operations.